Turbojet

| Turbojet | |

|---|---|

|

|

| Part of a series on Aircraft propulsion |

|

| Shaft engines (to drive propellers, rotors, ducted fans, or propfans) | |

|

|

| Reaction engines | |

Turbojets are the oldest kind of general-purpose jet engines. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s, although credit for the first turbojet is given to Whittle who was first to conceive, first to formally describe, first to patent and first to build a working engine. Von Ohain, in comparison, was first to get a turbojet into the air powering an aircraft.

Turbojets consist of an air inlet, an air compressor, a combustion chamber, a gas turbine (that drives the air compressor) and a nozzle. The air is compressed into the chamber, heated and expanded by the fuel combustion and then allowed to expand out through the turbine into the nozzle where it is accelerated to high speed to provide propulsion.[1]

Turbojets are quite inefficient (if flown below about Mach 2) and very noisy. Most modern aircraft use turbofans instead for economic reasons. Turbojets are still very common in medium range cruise missiles, due to their high exhaust speed, low frontal area and relative simplicity.

Contents |

History

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.[2] His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

Practical axial compressors were made possible by ideas from A.A.Griffith in a seminal paper in 1926 ("An Aerodynamic Theory of Turbine Design").

On 27 August 1939 the Heinkel He 178 became the world's first aircraft to fly under turbojet power with test-pilot Erich Warsitz at the controls[3], thus becoming the first practical jet plane. The first two operational turbojet aircraft, the Messerschmitt Me 262 and then the Gloster Meteor entered service towards the end of World War II in 1944.

A turbojet engine is used primarily to propel aircraft, but has been used for other vehicles, such as cars. Air is drawn into the rotating compressor via the intake and is compressed to a higher pressure before entering the combustion chamber. Fuel is mixed with the compressed air and ignited by a flame in the eddy of a flame holder. This combustion process significantly raises the temperature of the gas. Hot combustion products leaving the combustor expand through the turbine where power is extracted to drive the compressor. Although this expansion process reduces the turbine exit gas temperature and pressure, both parameters are usually still well above ambient conditions. The gas stream exiting the turbine expands to ambient pressure via the propelling nozzle, producing a high velocity jet in the exhaust plume. If the momentum of the exhaust stream exceeds the momentum of the intake stream, the impulse is positive, thus, there is a net forward thrust upon the airframe.

Early generation jet engines were pure turbojets, designed initially to use a centrifugal compressor (as in the Heinkel HeS 3), and very shortly afterwards began to use Axial compressors (as in the Junkers Jumo 004) for a smaller diameter to the overall engine housing. They were used because they were able to achieve very high altitudes and speeds, much higher than propeller engines, because of a better compression ratio and because of their high exhaust speed. However, they were not very fuel efficient. Modern jet engines are mainly turbofans, where a proportion of the air entering the intake bypasses the combustor; this proportion depends on the engine's bypass ratio. This makes turbofans much more efficient than turbojets at high subsonic/transonic and low supersonic speeds.

One of the most recent uses of turbojet engines was the Olympus 593 on Concorde. Concorde used turbojet engines because it turns out that the small cross-section and high exhaust speed is ideal for operation at Mach 2. Concorde's engine burnt less fuel to produce a given thrust for a mile at Mach 2.0 than a modern high-bypass turbofan such as General Electric CF6 at its Mach 0.86 optimum speed. Concorde's airframe, however, was far less efficient than that of any subsonic airliner.

Turbojet engines had a significant impact on commercial aviation. Aside from being faster than piston engines, turbojets had greater reliability, with some models demonstrating dispatch reliability rating in excess of 99.9%. Pre-jet commercial aircraft were designed with as many as 4 engines in part because of concerns over in-flight failures. Overseas flight paths were plotted to keep planes within an hour of a landing field, lengthening flights. Turbojets' reliability allowed for three and two-engine designs, and more direct long-distance flights.[4]

Although ramjet engines are simpler in design as they have virtually no moving parts, they are incapable of operating at low flight speeds.

Notable vehicles using turbojets

- Heinkel He 178 - first airbreathing jet aircraft

- Messerschmitt Me 262 - first jet fighter

- De Havilland Comet - first jet airliner

- Concorde - Mach 2 airliner (also some models of the Tupolev Tu-144)

- Thrust2 - land speed record car that held the record for 14 years

- Boeing B-52 Stratofortress - a strategic bomber that has remained in service for more than 50 years

also many jet dragsters and other fighters.

Air intake

Preceding the compressor is the air intake (or inlet). It is designed to be as efficient as possible at recovering the ram pressure of the air streamtube approaching the intake. The air leaving the intake then enters the compressor. The stators (stationary blades) guide the airflow of the compressed gases.

Compressor

The compressor is driven by the turbine. The compressor rotates at very high speed, adding energy to the airflow and at the same time squeezing (compressing) it into a smaller space. Compressing the air increases its pressure and temperature.

In most turbojet-powered aircraft, bleed air is extracted from the compressor section at various stages to perform a variety of jobs including air conditioning/pressurization, engine inlet anti-icing and turbine cooling. Bleeding air off decreases the overall efficiency of the engine, but the usefulness of the compressed air outweighs the loss in efficiency.

Several types of compressor are used in turbojets and gas turbines in general: axial, centrifugal, axial-centrifugal, double-centrifugal, etc.

Early turbojet compressors had overall pressure ratios as low as 5:1 (as do a lot of simple auxiliary power units and small propulsion turbojets today). Aerodynamic improvements, plus splitting the compression system into two separate units and/or incorporating variable compressor geometry, enabled later turbojets to have overall pressure ratios of 15:1 or more. For comparison, modern civil turbofan engines have overall pressure ratios of 44:1 or more.

After leaving the compressor section, the compressed air enters the combustion chamber.

Combustion chamber

The burning process in the combustor is significantly different from that in a piston engine. In a piston engine the burning gases are confined to a small volume and, as the fuel burns, the pressure increases dramatically. In a turbojet the air and fuel mixture passes unconfined through the combustion chamber. As the mixture burns its temperature increases dramatically, but the pressure actually decreases a few percent.

The fuel-air mixture must be brought almost to a stop so that a stable flame can be maintained. This occurs just after the start of the combustion chamber. The aft part of this flame front is allowed to progress rearward. This ensures that all of the fuel is burned, as the flame becomes hotter when it leans out, and because of the shape of the combustion chamber the flow is accelerated rearwards. Some pressure drop is required, as it is the reason why the expanding gases travel out the rear of the engine rather than out the front. Less than 25% of the air is involved in combustion, in some engines as little as 12%, the rest acting as a reservoir to absorb the heating effects of the burning fuel.

Another difference between piston engines and jet engines is that the peak flame temperature in a piston engine is experienced only momentarily in a small portion of the full cycle. The combustor in a jet engine is exposed to the peak flame temperature continuously and operates at a pressure high enough that a stoichiometric fuel-air ratio would melt the can and everything downstream. Instead, jet engines run a very lean mixture, so lean that it would not normally support combustion. A central core of the flow (primary airflow) is mixed with enough fuel to burn readily. The cans are carefully shaped to maintain a layer of fresh unburned air between the metal surfaces and the central core. This unburned air (secondary airflow) mixes into the burned gases to bring the temperature down to something a turbine can tolerate.

Turbine

Hot gases leaving the combustor are allowed to expand through the turbine. Turbines are usually made up of high temperature metals such as inconel to resist the high temperature, and frequently have built-in cooling channels.

In the first stage the turbine is largely an impulse turbine (similar to a pelton wheel) and rotates because of the impact of the hot gas stream. Later stages are convergent ducts that accelerate the gas rearward and gain energy from that process. Pressure drops, and energy is transferred into the shaft. The turbine's rotational energy is used primarily to drive the compressor. Some shaft power is extracted to drive accessories, like fuel, oil, and hydraulic pumps. Because of its significantly higher entry temperature, the turbine pressure ratio is much lower than that of the compressor. In a turbojet almost two-thirds of all the power generated by burning fuel is used by the compressor to compress the air for the engine.

Nozzle

After the turbine, the gases are allowed to expand through the exhaust nozzle to atmospheric pressure, producing a high velocity jet in the exhaust plume. In a convergent nozzle, the ducting narrows progressively to a throat. The nozzle pressure ratio on a turbojet is usually high enough for the expanding gases to reach Mach 1.0 and choke the throat. Normally, the flow will go supersonic in the exhaust plume outside the engine.

If, however, a convergent-divergent "de Laval" nozzle is fitted, the divergent (increasing flow area) section allows the gases to reach supersonic velocity within the nozzle itself. This is slightly more efficient on thrust than using a convergent nozzle. There is, however, the added weight and complexity since the con-di nozzle must be fully variable to cope with engine throttling.

Net thrust

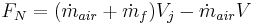

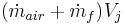

The net thrust  of a turbojet is given by:[5][6]

of a turbojet is given by:[5][6]

where:

-

is the rate of flow of air through the engine

is the rate of flow of fuel entering the engine

is the speed of the jet (the exhaust plume) and is assumed to be less than sonic velocity

is the true airspeed of the aircraft

represents the nozzle gross thrust

represents the ram drag of the intake.

If the speed of the jet is equal to sonic velocity the nozzle is said to be choked. If the nozzle is choked the pressure at the nozzle exit plane is greater than atmospheric pressure, and extra terms must be added to the above equation to account for the pressure thrust.[7]

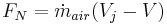

The rate of flow of fuel entering the engine is very small compared with the rate of flow of air.[5] If the contribution of fuel to the nozzle gross thrust is ignored, the net thrust is:

The speed of the jet  must exceed the true airspeed of the aircraft

must exceed the true airspeed of the aircraft  if there is to be a net forward thrust on the airframe. The speed

if there is to be a net forward thrust on the airframe. The speed  can be calculated thermodynamically based on adiabatic expansion.[8]

can be calculated thermodynamically based on adiabatic expansion.[8]

Thrust to power ratio

A simple turbojet engine will produce thrust of approximately: 2.5 pounds force per horsepower (15 mN/W).

Afterburner

An afterburner or "reheat jetpipe" is a device added to the rear of the jet engine. It provides a means of spraying fuel directly into the hot exhaust, where it ignites and boosts available thrust significantly; a drawback is its very high fuel consumption rate. Afterburners are used almost exclusively on supersonic aircraft – most of these are military aircraft. The two supersonic civilian transports, Concorde and the TU-144, also utilized afterburners but these two have now been retired from service. Scaled Composites White Knight, a carrier aircraft for the experimental SpaceShipOne suborbital spacecraft, also utilizes an afterburner.

Thrust reverser

A thrust reverser is, essentially, a pair of clamshell doors mounted at the rear of the engine which, when deployed, divert thrust normal to the jet engine flow to help slow an aircraft upon landing. They are often used in conjunction with spoilers. The accidental deployment of a thrust reverser during flight is a dangerous event that can lead to loss of control and destruction of the aircraft (see LaudaAir Flight 004). Thrust reversers are more convenient than drogue parachute, though mechanically more complex and expensive.

Cycle improvements

Thermodynamics of a jet engine are modelled approximately by a Brayton Cycle.

Increasing the overall pressure ratio of the compression system raises the combustor entry temperature. Therefore, at a fixed fuel flow and airflow, there is an increase in turbine inlet temperature. Although the higher temperature rise across the compression system, implies a larger temperature drop over the turbine system, the nozzle temperature is unaffected, because the same amount of heat is being added to the system. There is, however, a rise in nozzle pressure, because overall pressure ratio increases faster than the turbine expansion ratio. Consequently, net thrust increases, while specific fuel consumption (fuel flow/net thrust) decreases.

Thus turbojets can be made more fuel efficient by raising overall pressure ratio and turbine inlet temperature in union. However, better turbine materials and/or improved vane/blade cooling are required to cope with increases in both turbine inlet temperature and compressor delivery temperature. Increasing the latter requires better compressor materials.

Minimizing heat losses and optimizing the inlet temperature ratio will increase the system's useful work and the thermal efficiency of the turbo jet engine.

Early designs

Early German engines had serious problems controlling the turbine inlet temperature. A lack of suitable alloys due to war shortages meant the turbine rotor and stator blades would sometimes disintegrate on first operation and never lasted long. Their early engines averaged 10–25 hours of operation before failing—often with chunks of metal flying out the back of the engine when the turbine overheated. British engines tended to fare better, running for 150 hours between overhauls. A few of the original fighters still exist with their original engines, but many have been re-engined with more modern engines with greater fuel efficiency and a longer TBO (such as the reproduction Me-262 powered by General Electric J85s).

The United States had the best materials because of their reliance on turbo/supercharging in high altitude bombers of World War II. For a time some US jet engines included the ability to inject water into the engine to cool the compressed flow before combustion, usually during takeoff. The water would tend to prevent complete combustion and as a result the engine ran cooler again, but the planes would take off leaving a huge plume of smoke.

Today these problems are much better handled, but temperature still limits turbojet airspeeds in supersonic flight. At the very highest speeds, the compression of the intake air raises the temperatures throughout the engine to the point that the turbine blades would melt, forcing a reduction in fuel flow to lower temperatures, but giving a reduced thrust and thus limiting the top speed. Ramjets and scramjets do not have turbine blades; therefore they are able to fly faster, and rocket engines run even hotter still.

At lower speeds, better materials have increased the critical temperature, and automatic fuel management controls have made it nearly impossible to overheat the engine.

See also

- Brayton Cycle

- Variable Cycle Engine

- Exoskeletal engine

- Air start system

- Turbojet development at the RAE

References

- ↑ "Turbojet Engine". NASA Glenn Research Center. http://www.grc.nasa.gov/WWW/K-12/airplane/aturbj.html. Retrieved 2009-05-06.

- ↑ Maxime Guillaume,"Propulseur par réaction sur l'air," French patent FR 534801 (filed: 3 May 1921; issued: 13 January 1922)

- ↑ Warsitz, Lutz: THE FIRST JET PILOT - The Story of German Test Pilot Erich Warsitz (p. 125), Pen and Sword Books Ltd., England, 2009, ISBN 9781844158188

- ↑ Larson, George C. (April/May 2010), ""Old Faithful"", "Air & Space" 25 (1): 80, http://www.airspacemag.com

- ↑ 5.0 5.1 Cumpsty, Nicholas (2003). "3.1". Jet Propulsion (2nd ed.). Cambridge University Press. ISBN 0-521-541441.

- ↑ "Turbojet Thrust". NASA Glenn Research Center. http://www.grc.nasa.gov/WWW/K-12/airplane/turbth.html. Retrieved 2009-05-06.

- ↑ Cumpsty, Jet Propulsion, Section 6.3

- ↑ [http://web.mit.edu/16.unified/www/SPRING/propulsion/notes/node85.html#SECTION06364000000000000000 MIT.EDU Unified: Thermodynamics and Propulsion Prof. Z. S. Spakovszky - Turbojet Engine]

- Springer, Edwin H. (2001). Constructing A Turbocharger Turbojet Engine. Turbojet Technologies.

External links

|

||||||||||||||||||||||||||||||

|

||||||||||||||